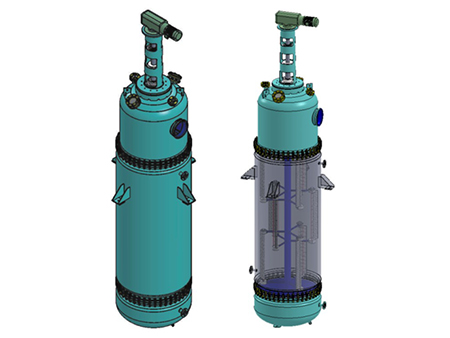

Glass Lined Wiped Film Evaporator (WFE)

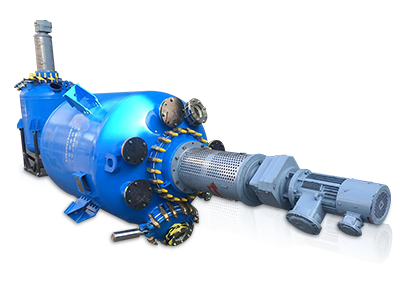

Wiped film evaporator (WFE) is a thin film evaporator that plays a vital role in evaporation applications involving corrosive substances. As an experienced anti-corrosion process equipment manufacturer, we supply glass-lined wiped film evaporators that are specifically designed for handling materials with characteristics of high viscosity, high heat sensitivity, high fouling, and high boiling points.

To ensure the optimal performance in corrosion resistance, all internal parts of the wiped film evaporator coming into contact with the corrosive liquids or gases are lined with technical enamel, PTFE or other non-metallic materials featuring corrosion resistance. The adoption of these corrosion-resistant materials provides inner surface of the wiped film evaporator with an effective protection against corrosive substance, therefore ensuring high durability and long service life.

Design Pressure

Vessel: Full Vacuum (FV) to 0.25Mpa

Jacket: 0.6MPa

Standard HG/T4299-2019

| Model | 0.25 | 0.5 | 1.0 | 2.0 | 3.0 | 4.0 | 5.0 | 6.0 | 7.0 | 8.0 | 9.0 | 10.0 | 12.5 |

| 219 | 300 | 500 | 600 | 600 | 800 | 900 | 900 | 1000 | 1000 | 1200 | 1200 | 1300 | |

| 325 | 400 | 600 | 700 | 700 | 900 | 1000 | 1000 | 1100 | 1100 | 1300 | 1300 | 1450 | |

| 650 | 800 | 900 | 1350 | 1850 | 1830 | 2010 | 2370 | 2460 | 2750 | 2600 | 2900 | 3200 | |

| 385 | 425 | 650 | 845 | 845 | 880 | 905 | 400 | 430 | 430 | 470 | 470 | 470 | |

| 185 | 205 | 265 | 545 | 545 | 650 | 675 | 675 | 680 | 680 | 750 | 750 | 750 | |

| 900 | 1155 | 1225 | 1380 | 1380 | 1550 | 1665 | 1665 | 1740 | 1740 | 2000 | 2100 | 2200 | |

| 2150 | 2615 | 3070 | 4150 | 4650 | 4940 | 5275 | 5145 | 5335 | 5630 | 5840 | 6250 | 6800 | |

| 330 | 350 | 365 | 475 | 475 | 475 | 475 | 650 | 650 | 650 | 660 | 680 | 680 | |

| 0.31 | 0.57 | 1.08 | 2.16 | 3.13 | 4.04 | 5.11 | 6.15 | 7.13 | 8.17 | 9.09 | 10.25 | 12.9 | |

| 0.75 | 1.5 | 1.5 | 2.2 | 3 | 4 | 5.5 | 5.5 | 5.5 | 7.5 | 7.5 | 7.5 | 11 | |

| 245 | 385 | 475 | 1090 | 1495 | 1810 | 2370 | 2460 | 2800 | 3100 | 4000 | 4500 | 4900 |

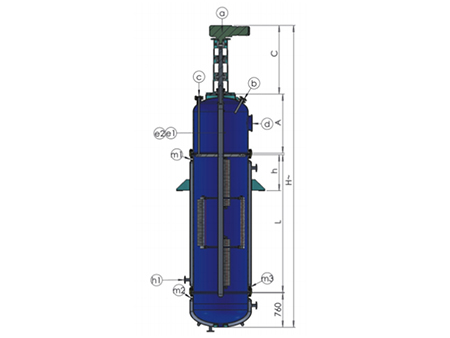

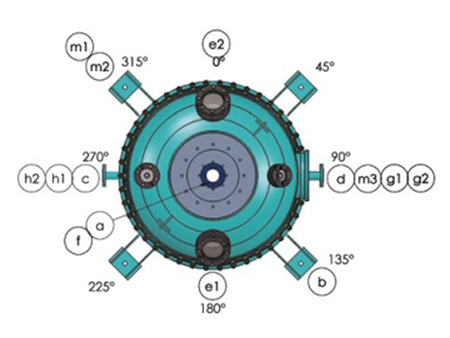

| Model | a | b | c | d | e1 | e2 | f | g1 | g2 | h1 | h2 | m1 | m2 | |

| 50 | 50 | 50 | 50 | / | / | 25 | 20 | / | 20 | / | G1/2" | / | G1/2" | 65 | 50 | 65 | 65 | / | / | 50 | 25 | / | 25 | / | G1/2" | / | G1/2" | 80 | 50 | 100 | 100 | 100 | 100 | 65 | 40 | / | 40 | / | G1/2" | / | G1/2" | 125 | 50 | 50 | 125 | 100 | 100 | 80 | 50 | 50 | 50 | 50 | G1/2" | G1/2" | G1/2" | 125 | 50 | 50 | 125 | 100 | 100 | 80 | 50 | 50 | 50 | 50 | G1/2" | G1/2" | G1/2" | 125 | 50 | 50 | 150 | 125 | 125 | 80 | 50 | 50 | 50 | 50 | G1/2" | G1/2" | G1/2" | 125 | 50 | 50 | 150 | 125 | 125 | 100 | 50 | 50 | 50 | 50 | G1/2" | G1/2" | G1/2" | 125 | 50 | 50 | 200 | 125 | 125 | 100 | 50 | 50 | 50 | 50 | G1/2" | G1/2" | G1/2" | 125 | 50 | 65 | 200 | 125 | 125 | 100 | 50 | 50 | 50 | 50 | G1/2" | G1/2" | G1/2" | 125 | 50 | 65 | 250 | 125 | 125 | 100 | 50 | 50 | 50 | 50 | G1/2" | G1/2" | G1/2" | 125 | 50 | 65 | 250 | 125 | 125 | 100 | 50 | 50 | 50 | 50 | G1/2" | G1/2" | G1/2" | 125 | 50 | 65 | 300 | 125 | 125 | 100 | 50 | 50 | 50 | 50 | G1/2" | G1/2" | G1/2" | 125 | 50 | 65 | 400 | 125 | 125 | 150 | 100 | 100 | 100 | 100 | G1/2" | G1/2" | G1/2" |