-

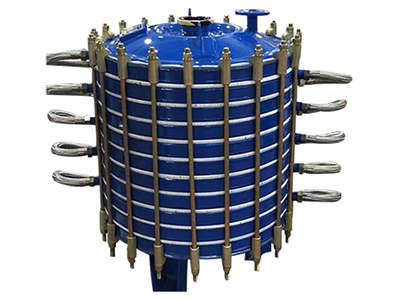

- Silicon carbide heat exchanger is one of the most used heat exchange equipment. Nevertheless, the materials and technologies needed are relatively costly. So, to save the cost, it is important to extend the machine’s service life. The approach lies in cleaning at regular intervals.

Common ways of cleaning a silicon carbide heat exchanger are through mechanical means, high-pressure water, and chemical means. Learn More

-

- Reducing the resistance of the silicon carbide heat exchanger can increase the heat exchange coefficient and the average flow rate of the medium between the condensing plates. But the power consumption of the circulating pump and the equipment cost go up when the resistance is reduced. Learn More

-

- Before installation, make sure no part is missing or broken;

Before installation, make sure the glass-lined layer is clean and intact;

During installation, tools like crowbar and hammer should be kept away from the reactor; all installation staff should wear rubber-soled shoes;

During installation, make sure the reactor clamp is stressed uniformly; to guarantee the installation quality, no broken parts should be used;Learn More

-

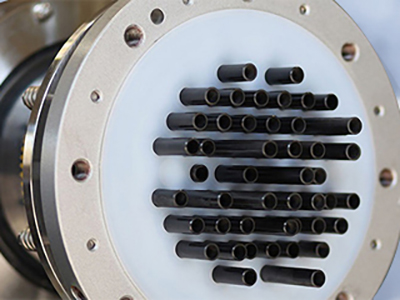

- Purchase advice for glass-lined condenser, accessory of the glass-lined reactor

A glass-lined condenser is an important partner of a glass-lined reactor, and its role is significant during the cooling process of heating. When selecting them, attention should also be paid to the cooling area and the condenser’s parameters. Learn More

- Purchase advice for glass-lined condenser, accessory of the glass-lined reactor

-

- Now that you have purchased the glass-lined reactor you want, don’t forget that regular testing and maintenance are of importance, which can reduce machine faults and prolong its service life. Below are some of the approaches of maintenance.

Check that all the valves on the glass-lined reactor are in good working condition and can be used. Repair the faulty part immediately. Learn More