Drafter of Industry Standards

Drafter of Industry StandardsWe have participated in the drafting of several domestic industry standards relating to glass-lined equipment used in chemical process industries.

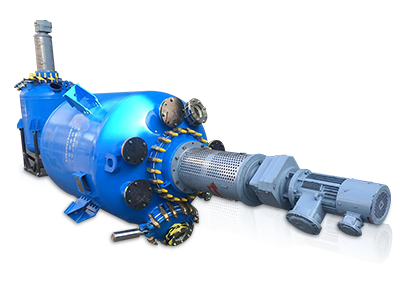

- Drafting unit of China's chemical industry standard of HG/T 4299-2018 Glass-Lined Wiped Film Evaporator Structure and Parameters

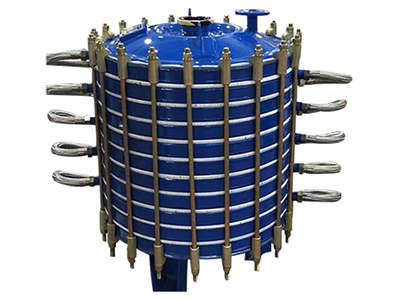

- Drafting unit of China's chemical industry standard of HG/T 4298-2018 Glass-Lined Porous Plate-Type Condenser

- Standard drafting participation unit of industry standard of HG/T 2130-2021 Glass-Lined Pipes

- Standard drafting participation unit of industry standard of HG/T 2134-2021 Glass-Lined 90° Elbows

- Standard drafting participation unit of industry standard of HG/T 2132-2021 Glass-Lined 45° Elbows

- Standard drafting participation unit of industry standard of HG/T 2131-2021 Glass-Lined 30° Elbows

- Standard drafting participation unit of industry standard of HG/T 3218-2016 Glass-Lined Discharge Valves

- Standard drafting participation unit of industry standard of HG/T 3217-2016 Glass-Lined Discharge Valves

- Standard drafting participation unit of industry standard of HG/T3217~3220-2016 Glass-Lined Valves

- Standard drafting participation unit of industry standard of HG/T 2145.2-2015 Handhole with Glass Sight for Glass-Lined Vessel

- Standard drafting participation unit of industry standard of HG/T 2136-2022 Glass-Lined Tee Joint and Cross Joint

- Drafting unit of China's chemical industry standard of HG/T 2637~2638-2017 Testing Methods of Geometric Size for Glass-Lined Parts

Technical Materials

Technical MaterialsTechnical Enamels

German technical enamels are applied to Qianqiao's glass lined products, including glass lined piping, glass line valves and glass lined process equipment, that have demonstrated their corrosion resistance performance in numerous applications.

The industrial enamel used in glass-lining process can provide excellent resistance to acids and alkaline mediums. It also gives exceptional smooth surface finish while delivering high resistance to abrasive substances, ensuring durable and long lasting surface. Since vitreous enamel is non porous, no residual chemicals or hazardous bacteria can adhere to the enamel surface.

Benefits of Technical Enamels

- Protecting inner surface of process equipment from corrosion

- Protecting metal surface from rust and physical damage

- Providing optimal combination of strength and flexibility for metal

- Providing resistance to abrasion and wear

- Preventing the growth of bacteria

- Allowing high process temperatures

- Impervious to contamination

- Improving aesthetic appearance of equipment

- Maintenance free, long service life

- Easy to clean

Cold Spraying Technology

Cold Spraying TechnologyThe application of technical enamels to metal surface is carried out by our sophisticated cold spraying technique. It is a solid-state coating process suitable for use in chemical and pharmaceutical industries to provide protection against corrosion and abrasion.

Unlike thermal spraying coating processes that may cause typical defects such as air bubbles and metal burrs, the cold spraying process overcomes these shortcomings and offers significant advantages without any appreciable grain growth.