Glass Lined Reactor

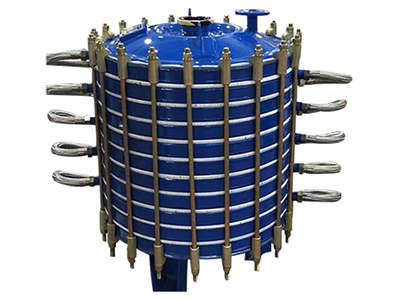

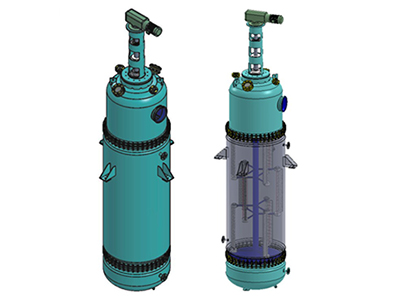

Our glass-lined reactors are designed and manufactured using European advanced technology and high-quality technical enamels, to meet the stringent requirements of the chemical and pharmaceutical industries. Additionally, we use cold spraying technology that can prevent coating quality defects which are frequently caused by high-temperature and thermal spraying method. Our dedication to the quality and durability guarantees that our glass-lined reactor can satisfy high industry standards, enabling our customers carry out chemical reactions with save operation, high efficiency and less cost.

The glass lined reactors are extensively utilized in various industrial processes to mix different types of chemicals. Particularly in chemical and pharmaceutical industries, corrosion resistance is an important factor need to be taken into account when conducting chemical reactions, since some corrosive chemicals can lead to damage of reactor components. In response to this challenge, we provide an effective anti-corrosion solution by offering reactors with glass linings that are corrosion resistant. This not only prolongs the service life of the chemical reaction equipment but also reduces the risk of contamination.