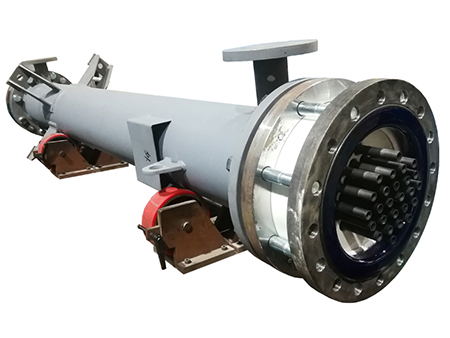

Silicon Carbide Heat Exchanger, Standard Type

This standard type silicon carbide heat exchanger is a shell and tube heat exchanger made with corrosion-resistant tube plates and silicon carbide (SiC) tubes, making it an ideal solution for various applications such as heating, cooling and condensation processes involving highly corrosive chemicals. With its advanced material and robust construction, our SiC shell and tube heat exchanger can provide optimal corrosion resistance performance and long service life for the chemical and pharmaceutical industries.

Typical Applications

- Bromine, Sulfuric Acid, Hydrofluoric Acid, Nitric Acid, Hydrochloric Acid, etc.;

- Alkalis;

- Halogenated Compounds;

- Salt Solutions;

- Organic Compounds;

Technical Data

- Each tube is subjected to test at pressure of 185 Bar before installation;

- Shell diameter range: DN100 to DN600;

- Standard length of tube: 1000 to 3000mm;

- Heat exchange area: 1 to 60m2;

- Tube diameter: 14mm, 19mm;

- Horizontal or vertical installation;

- Temperature range: -19°C to 100°C;

- Pressure range: -0.1MPa to 0.3MPa;

- CE, ATEX, FDA compliant

Comparison Chart of Thermal Conductivity

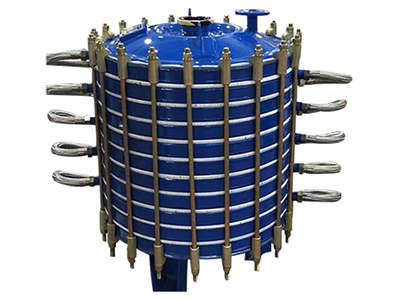

We can use double-tube plates design to separate process fluid from working fluid so that the two fluids will not be mingled even the O-ring breaks.

| Silicon carbide corrosion performance | |||

| Testing Environment Conc. Reagent | Corrosive Weight Loss | (mg/cm2yr) | |

| (Wt%) | Temperature (C) | Pressureless-sintered Silicon Carbide** No Free SiC)** | Reaction-bonded Silicon Carbide 12% SiC) |

| 98% H2SO4 | 100 | 1.8 | 55 |

| 50% NaOH | 100 | 2.6 | >1000 |

| 53% HF | 25 | < 0.2 | 7.9 |

| 85% H3PO4 | 100 | < 0.2 | 8.8 |

| 70% HNO3 | 100 | < 0.2 | 0.5 |

| 45% KOH | 100 | < 0.2 | >1000 |

| 25% HCI | 70 | < 0.2 | 0.9 |

| 10% HF plus 57% HNO3 | 25 | < 0.2 | >1000 |

| Qianqiao produces every SiC heat exchanger with pressureless-sintered silicon carbide** | |||

Get in Touch

Questions? We are here to help.

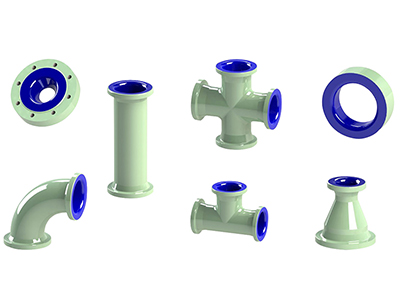

Related Solutions & Products