Silicon Carbide Heat Exchanger, F4/PFA Lined

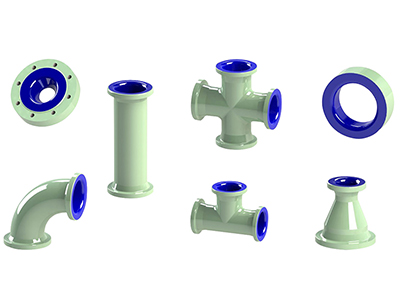

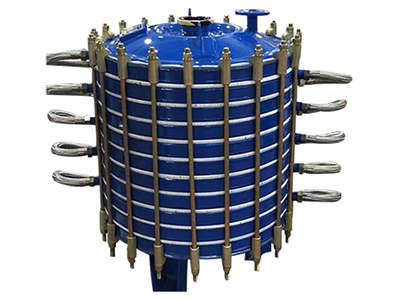

This F4/PFA lined silicon carbide heat exchanger is a shell & tube heat exchanger consisted of corrosion resistant tube plates and silicon carbide (SiC) tubes in conjunction with PTFE (F4) or PFA lining, with the ability to handle the challenges posed by highly corrosive chemicals in various applications of heating, cooling, and condensation.

Silicon carbide tube is known for its exceptional corrosion resistance, enabling it suitable for use in corrosive environments. In addition to its property of corrosion resistance, silicon carbide also features good mechanical strength, this makes the heat exchanger capable of withstanding extreme operating conditions.

F4 and PFA linings can provide unsurpassed resistance to corrosion for long-term reliability and guaranteed longevity, making the shell & tube heat exchanger an ideal choice for chemical and pharmaceutical industries to deal with highly corrosive substances.

- Bromine, Sulfuric Acid, Hydrofluoric Acid, Nitric Acid, Hydrochloric Acid, etc.;

- Alkalis;

- Halogenated Compounds;

- Salt Solutions;

- Organic Compounds;

- Each tube is subjected to test at pressure of 185 Bar before installation;

- Shell diameter range: DN100 to DN600;

- Standard length of tube: 1000 to 3000mm;

- Heat exchange area: 1 to 40m2;

- Tube diameter: 14mm, 19mm;

- Horizontal or vertical installation;

- Temperature range (F4 lining): -19°C to 120°C;

- Temperature range (PFA lining): -19°C to 200°C;

- Pressure range: -0.1MPa to 0.6MPa;

- CE, ATEX, FDA compliant

We can use double-tube plates design to separate process fluid from working fluid so that the two fluids will not be mingled even the O-ring breaks.

| Silicon carbide corrosion performance | |||

| Testing Environment Conc. Reagent | Corrosive Weight Loss | (mg/cm2yr) | |

| (Wt%) | Temperature (C) | Pressureless-sintered Silicon Carbide ** No Free SiC)** | Reaction-bonded Silicon Carbide 12% SiC) |

| 98% H2SO4 | 100 | 1.8 | 55 |

| 50% NaOH | 100 | 2.6 | >1000 |

| 53% HF | 25 | < 0.2 | 7.9 |

| 85% H3PO4 | 100 | < 0.2 | 8.8 |

| 70% HNO3 | 100 | < 0.2 | 0.5 |

| 45% KOH | 100 | < 0.2 | >1000 |

| 25% HCI | 70 | < 0.2 | 0.9 |

| 10% HF plus 57% HNO3 | 25 | < 0.2 | >1000 |

| Qianqiao produces every SiC heat exchanger with pressureless-sintered silicon carbide ** | |||