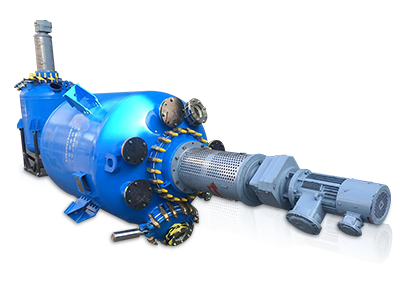

Purchase advice for glass-lined condenser, accessory of the glass-lined reactor

A glass-lined condenser is an important partner of a glass-lined reactor, and its role is significant during the cooling process of heating. When selecting them, attention should also be paid to the cooling area and the condenser’s parameters.

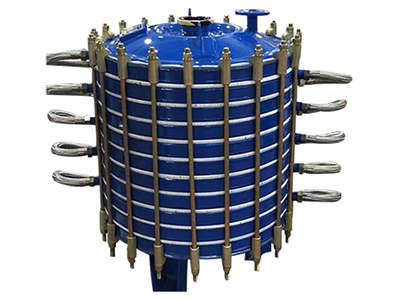

- There are two new types of glass-lined plate condenser: W-0.6 and W-1, each with the specifications of 2 pores and 6 pores. Replace or remove certain plates if there are parts broken after a certain period of use. In this way, the machine can avoid complete scrap and has a longer service life.

- During the operation of a condenser, hot air flow or gar flows into the condenser, and the cooling medium flows in the opposite direction. The cooling medium absorbs the heat of the hot air and removes it from the condenser. Plates of the same size are aligned with relatively small spacing, which makes the medium spread, come together, and flow, largely promoting the condenser’s efficiency and avoid air flow leak. For the condensing liquid part, tap water is a good choice. Sometimes, the stratification of the cooling water and a parallel flow configuration can increase the condensing efficiency. Therefore, apart from regularly cleaning the condenser, frequent examination and supplementation of condensing liquid is also important.

Above are the notes for buying a glass-lined plate condenser. Remember to check the heat exchange area.