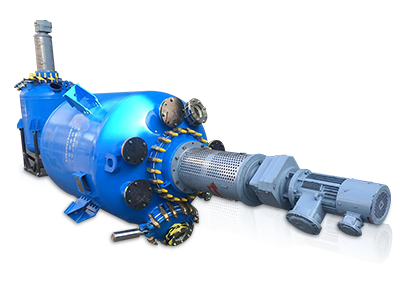

Here are the notes for the installation of glass-lined reactor:

- Before installation, make sure no part is missing or broken;

- Before installation, make sure the glass-lined layer is clean and intact;

- During installation, tools like crowbar and hammer should be kept away from the reactor; all installation staff should wear rubber-soled shoes;

- During installation, make sure the reactor clamp is stressed uniformly; to guarantee the installation quality, no broken parts should be used;

- Make sure the agitator rotates in the same direction as is shown in the graphical representation; reverse rotation will cause the falling of the agitator, breaking the glass lining.

- During the rigging (slinging), only the supporting base and the rings can be stressed while fragile parts like the clamp should be lifted softly and crashing.

- During the installation of the sight glass for the reactor, avoid over-tightening in case the glass will be broken.

- When the installation is finished, examine every component and the interior before dry run.