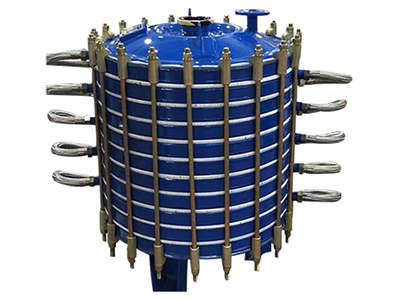

Silicon carbide heat exchanger is one of the most used heat exchange equipment. Nevertheless, the materials and technologies needed are relatively costly. So, to save the cost, it is important to extend the machine’s service life. The approach lies in cleaning at regular intervals.

Common ways of cleaning a silicon carbide heat exchanger are through mechanical means, high-pressure water, and chemical means. These methods all have some flaws:

- Fails to remove the water scale inside the heat exchanger;

- Fails to remove the deposits inside the heat exchanger;

- Chemical cleaning will corrodes the machine; remaining chemical solvent will again corrodes the equipment or even ruins the machine;

- The cleaning solution contains a large amount of toxic substances that inevitably pollutes the environment